Safety Products

SAFETY SAVES LIVES!

We can supply and install a wide range of safety products on your forklift,

warehouse equipment and warehouse facilities.

Blue Safety Light

Key Benefits:

Provides visual aid when reversing from Containers, racking aisles, cross aisles, blind aisles and docking areas.

Easy to install on any makes and models of forklift and warehouse equipment. Many companies are now incorporating this product into their fleet as it can be installed on new and well as old units without affecting the warranty or the performance of the trucks.

Red Zone Warning Light

Camera System

The system offers excellent visibility to the operator from a standard driving position. The Camera System enables the operator to stack easily on a high rack as he is able to view the operations up and above from the display monitor.

The Camera system enhances reducing the amount of damage caused by miscalculations made due to human error. Ideal for Reach truck and man down VNA operating above 7.5 m lift height.

Speed Control Device

The system monitors the travel speed of any IC engine powered forklift truck and indicates when a set speed has been exceeded. The system does not govern the engine and can be set to the required speed limit to suit the specific application requirements.

When the truck reaches the set speed limit it will automatically activate a beacon on top of the truck, a buzzer and an LED, both fitted in the cab.

When the truck speed drops below the set speed limit, the unit will reset and warnings will cease. The system does not affect the performance of the truck as it is designed to act as a warning only.

Key Features:

- Throttle Cable Speed Control

- Simple set up and low maintenance

- Increases site safety

- Reduces fuel consumption

- Suitable for gas or diesel trucks with conventional torque converter transmission

- Works only when truck is moving, so that lift capability is not affected

Key Benefits:

- Fork trucks conform to site speed limit

- Increased site safety

- Preventing operator abuse

- Reduce stress on the engine

- Fuel bill savings

- Reduced tyre wear and tear

Proximity Sensors

Whenever an imminent collision risk is spotted, visual and acoustic signals warn the operator, SIS automatically slows down and prevents the movement of the forklift truck before the accident occurs. A compact design allows the sensor to be easily placed on the rear part of the truck.

How it works

Whenever an obstacle is detected by the ultrasonic sensor placed at the rear of the vehicle, the driver is warned through acoustic and visual signals given by the display placed in the cabin, slowing down and blocking are automatically activated thus avoiding the risk of collision.

ALPHALIFT SIS Proximity system is an active maneuvering system for forklift trucks and industrial vehicles which detects potential obstacles in the operating range of forklift trucks. Whenever an imminent collision risk is spotted, visual and acoustic signals warn the operator, SIS automatically slows down and prevents the movement of the forklift truck before the accident occurs.

SIS – Mainly operates in two critical situations:

1) Reverse maneuvering,

2) Load lifting.

Overload Warning Device

The system warns the operator that a pre-set lifting pressure limit has been exceeded. The system is fully adjustable and any level can be set within the limits of the 250 bar pressure transducer fitted within the load cell. Site safety is improved and the lifting performance is not affected.

If the operator attempts to lift above the pre-set pressure a warning signal is given via a buzzer and a beacon situated on the truck to alert the operator. The audible and visual alarm warns the operator that he has tried to exceed the lifting capacity specified for that truck.

Forklift Movement Alarm

HOW IT WORKS

When, at an intersection, Safe Traffic microwave sensor detects an approaching vehicle, the central control unit activates the visual and acoustic alarms with the aim of alerting other drivers as well as pedestrians in the area of potential risk.

NO INSTALLATION ON VEHICLE REQUIRED

The device is placed on the wall next to the intersection, no element requires installation on vehicles operating in the area.

MODULAR

Central control unit is preset, with multiple inputs and outputs, to be integrated with a maximum of 4 sensors: This means that the device can be managed modularly and can be adapted to any lay-out of the working area by positioning more sensors and alarms.

CUSTOMIZATION

Safe Traffic offers maximum operational flexibility through a wide range of configurable parameters offering a choice of 64 continuous tones, with adjustment up to 105 dB, for the acoustic alarm signal.

Safety SPRINGBELT™

The SPRINGBELT™ is now UPGRADED to include an improved self centering spring-loaded mount. This means that it’s always in the right place to put on. At the same time installation is a lot easier and there is also a lot less strain on the seat base, to which SPRINGBELT™ is often mounted.

Why is SPRINGBELT™ different?

Most fork lift truck seat belts are a development of automobile seat belts and as such have the buckles beside the seat where they can be difficult and frustrating to deploy and are forgotten. Loose belts simply fall down out of sight and out of mind.

The SPRINGBELT™ concept is simple.

It’s EASY – QUICK – SIMPLE – SAFE

The SPRINGBELT™ is apparent even as the operator approaches the equipment.

And then, as they sit down it is quick, easy and hard to avoid.

Over Speed Warning System

The system monitors the travel speed of any IC engine powered forklift truck and indicates when a set speed has been exceeded. The system does not govern the engine and can be set to the required speed limit to suit the specific application requirements.

When the truck reaches the set speed limit it will automatically activate a beacon on top of the truck, a buzzer and an LED, both fitted in the cab.

When the truck speed drops below the set speed limit, the unit will reset and warnings will cease. The system does not affect the performance of the truck as it is designed to act as a warning only.

Key Benefits:

Site safety is increased

Reduced insurance premiums can be achieved

Fleet Management System

Drivers can log in via a manual key code (4 digits), or an RFID fob available at additional cost.

The system communicates via Wi-Fi with a SQL-based data service and client software installed on PCs / VMs, providing real time information, and automatically generated reports and alerts. A highly flexible daily checks system also allows your truck maintenance procedures to go paper free, with associated cost and environmental benefits for your company.

Features:

- Color LCD display.

- Suitable for Gas, Diesel & Electric Trucks.

- Eliminates keys, increasing security.

- Up to 1,000 drivers with a combination of key codes and RFID fobs.

- Up to 3,000 log memory – oldest entries are overwritten automatically when full.

- Start vehicles with keypad or RFID fob.

- Fully configurable operators checklist questions.

- Impact Detection (Variable sensitivity and handling options)

- Recorded events can be filtered, graphed and reported using included software.

- Certain events can be reported instantly via email.

- Automatic driver code expiration. Automatic lockout upon reaching retraining date.

- Instant Messaging Service. Simple messages can be sent to trucks, and replied to by the operator with set responses.

- Automatic data exchange via Wi-Fi using existing infrastructure where available.

Benefits:

- Drivers can only drive what they are allowed to.

- Increased site safety and reduced damage from increased accountability.

- Truck usage and utilization monitoring increase your efficiency.

- Driver retraining alerts and license monitoring.

Back-Up Alarm

A forklift Back-Up Alarm can be installed onto a forklift or warehouse equipment to alert a pedestrian in close proximity when this particular forklift/Warehouse equipment is in reverse.

Benefits:

They actually will prevent pedestrian forklift accidents.

Note: The back-up alarm is not recommended if you have many forklift trucks and warehouse equipment in the same facility.

Recommendation: Blue Safety Light.

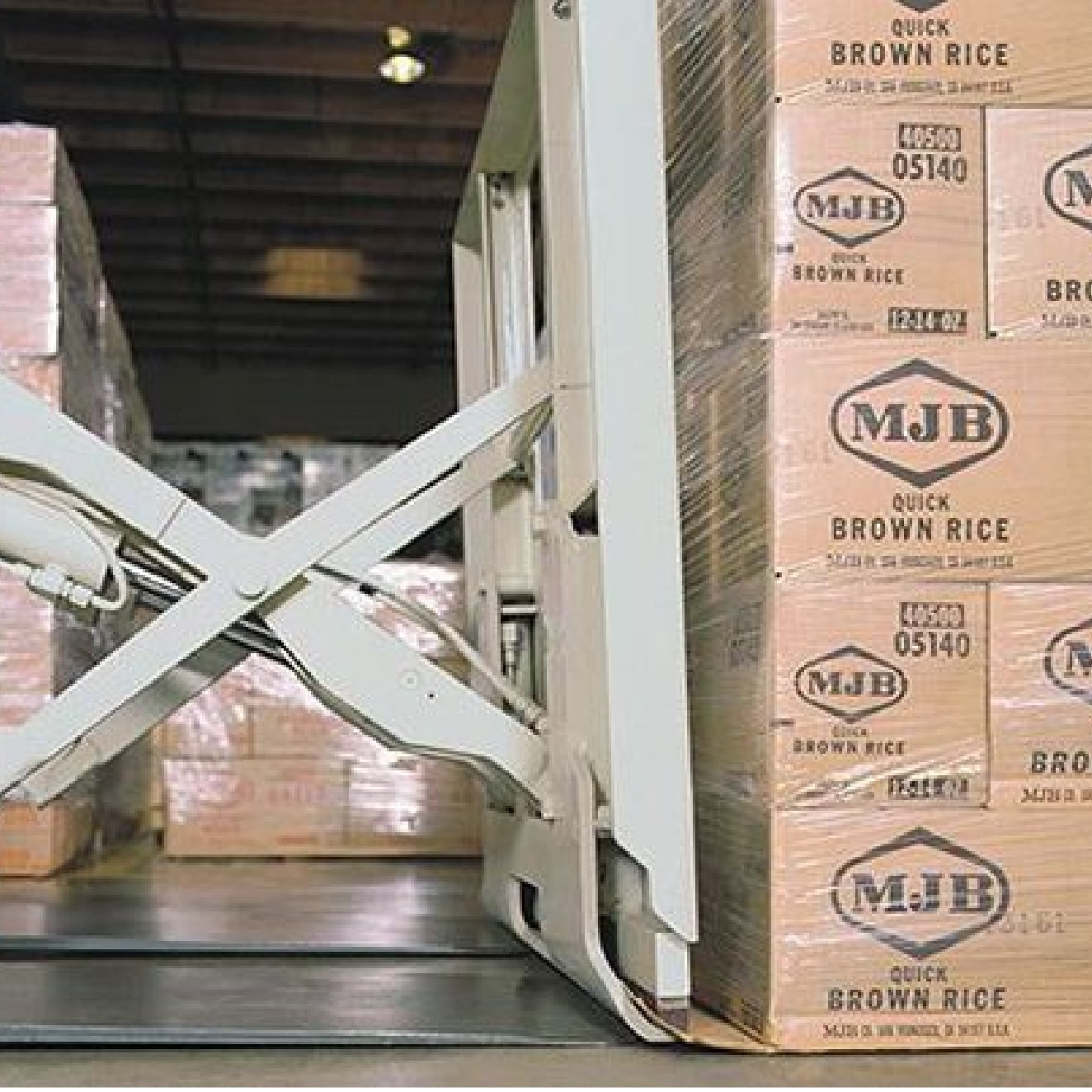

Warehouse Management System (WMS)

A WMS also provides visibility into an organization’s inventory at any time and location, whether in a facility or in transit.

Warehouse Management System (WMS)

A warehouse management system (WMS) consists of software and processes that allow organizations to control and admin is warehouse operations from the time goods or materials enter a warehouse until they move out.

What does a WMS do?

Warehouses sit at the center of manufacturing and supply chain operations because they hold all of the material used or produced in those processes, from raw materials to finished goods. The purpose of a WMS is to help ensure that goods and materials move through warehouses in the most efficient and cost-effective way. A WMS handles many functions that enable these movements, including inventory tracking, picking, receiving, and put away.